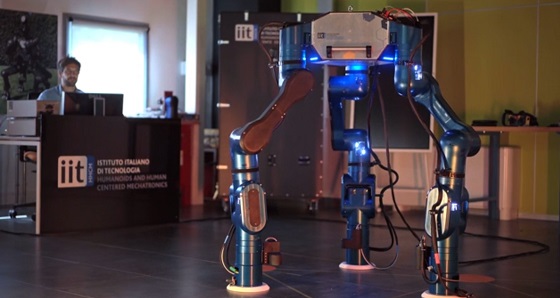

Researchers at Istituto Italiano di Tecnologia (IIT – Italian Institute of Technology) have recently realized a new prototype robotic platform for space applications. The new robot, called MARM, has three limbs that can be used to walk, move, grasp and transport payload modules while self-relocating itself on the space infrastructure under microgravity environment.

The robot is meant to assist astronauts in assembling and maintaining infrastructures while they are in space or, in the future, on other planets. The MARM prototype will be tested in a physical simulator arrangement prior to the development of the space-qualified version. The robot was designed and manufactured by IIT, in collaboration with Leonardo S.p.A and GMV.

Robotic applications in the field of space exploration present unique environments, conditions and opportunities for the development of new platforms. In fact, while the technologies required for robotic control, locomotion and manipulation on Earth are quite advanced, the conditions of the orbital environment, such as the microgravity are posing new challenges to the robotics research community.

Developing tools to assist astronauts in installing, inspecting, maintaining and repairing space infrastructures is the goal of the MIRROR (Multi-arm Installation Robot for Readying ORUs and Reflectors) project, funded by the European Space Agency (ESA), where the new robot has been born. Therefore, in the framework of the MIRROR project, IIT researchers realized the MARM (Multi-Arm Relocatable Manipulator) platform, which is a prototype robotic system capable of performing grasping, transportation and assembling modules, while moving itself on the space infrastructure.

The robot was designed and manufactured by IIT’s Human and Humanoid Centered Mechatronics Lab, coordinated by Nikolaos Tsagarakis, in collaboration with Leonardo S.p.A and GMV. The MARM robot represents the last generation of robot realized by Nikolaos Tsagarakis’ team, therefore his research group at IIT designed and produced also the humanoid robot WALK-MAN and the Centaur-like robot CENTAURO, and is working on the modular configurable collaborative robot CONCERT funded by the EU.

The MARM robotic platform consists of a central body, three limbs and a docking device (useful for both powering and sending/receiving data). It was built following a computational design approach, which considered and optimized the robot performance related to mobility and flexibility. In fact, the kinematics and transport/operational capacity were tested, in both the presence and absence of gravity, considering different kinematic models, which differed in the length and conformation of limbs, links and joints.

The MARM platform can thus use its three limbs to move around, grasping the standard interconnections on the station’s surfaces and crawling over them, and also to assemble and position components (in particular modular hexagon tiles, 1.2 m wide and 0.2 m thick, weighing about 12 kg) and to manipulate the so-called Orbital Replacement Units (ORUs).

MARM’s three limbs, which are connected to the central pelvis base, represent the main difference of this robot compared to previously developed technologies: the three limbs endow the robot with greater locomotion and manipulation flexibility and, at the same time, a wider manipulation range, allowing it to transport large payloads and assemble and install them, even in bi-manual mode.

In addition, thanks to the three limbs arrangement, the robot is capable of performing full body motions while once in position, the limbs used for anchoring can facilitate the assembly operation by adjusting the MARM central pelvis base, reducing the forces transferred to the station truss. This is one of the main advantages of having multiple limbs instead of using the same limb for crawling and assembly.

According to the envisioned scenario, the MARM platform will be able, through its electromechanical and control components and thanks to a perception system and the continuous exchange of inputs/outputs, to pick up a payload from a store, relocate itself while carrying it, and assemble it at the desired location.

The MARM platform prototype will be used to evaluate the above scenario in a physical simulator arrangement in order to assess the feasibility of such solution prior to the development of the space-qualified version.

Credit: IIT-Istituto Italiano di Tecnologia